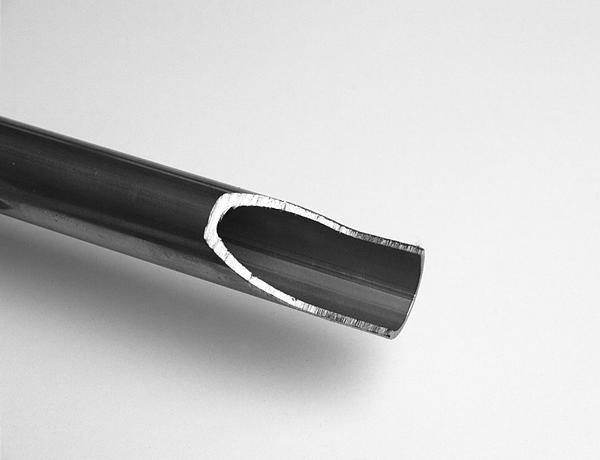

A company produces tube bending parts for the automotive industry from welded and annealed tubes. For this purpose, the workpieces must be bent and then pressed. In the course of this manufacturing process, the internal weld seam of the tubes must not be located in the bending radius, otherwise cracks could form in the workpiece.

The company was looking for a sensor technology that was capable of reliably identifying the position of the weld seam inside the tube before bending. The particular challenge: In the case of non-annealed workpieces, a very distinct heat-affected zone can be seen on both sides along with a weld seam, which contrasts with the background in terms of color. In the case of annealed tubes, however, such tempering colors either disappear completely or are only very faintly visible as a result of 'normalizing'.

The desired solution had to be compact, able to be integrated into the production process without major assembly effort, and also enable both fast and extremely reliable identification of the weld seam.

ipf electronic recommended a color sensor of the OF50 series, more precisely the OF500180, which not only met the greatest challenges in the project, but also fulfilled the customer's wishes with regard to easy installation and integration.

The complete application report can be found in the PDF file below.