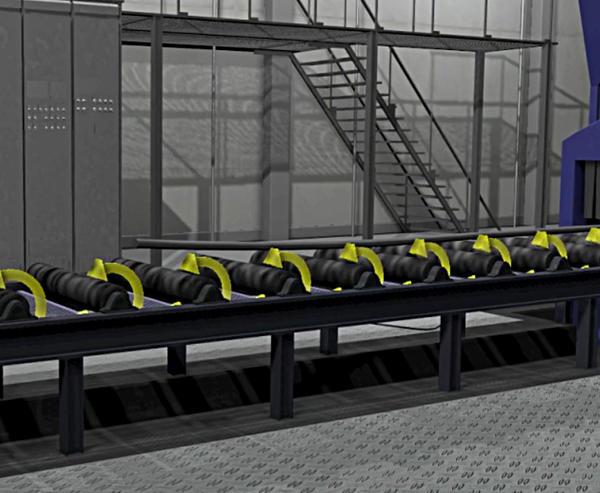

In a hot rolling operation, bar stock that is transported from a sandblasting plant via a roller table to a limit stop is to be removed in the area of the limit stop for further processing. As soon as the bar material touches the limit stop, the roller table must stop to prevent surface damage to the bars by the rotating rollers.

The extremely limiting installation situations at the plant prevent the use of conventional sensor technology, so that only the limit stop itself can be considered as a detection area.

The solution from ipf electronic is as simple as it is effective: A signal inverter of the VY85 series, which is used as a contact relay between the limit stop and the control (unit).

The complete application report can be found in the following PDF file.