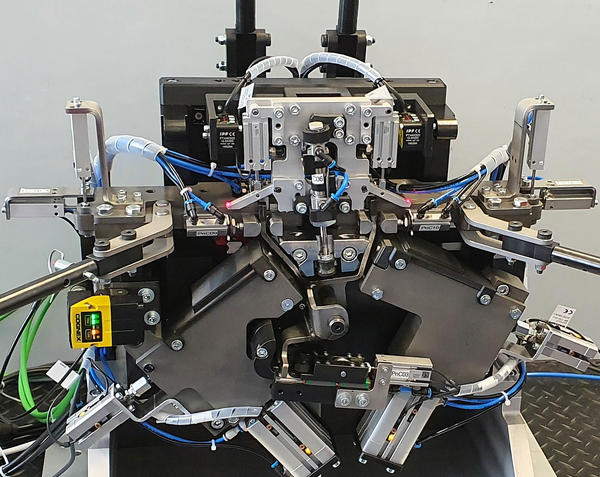

BEAS Technology GmbH developed a special system for the measurement of car gearshift forks, which are straightened with the same solution in case of deviations from the tolerances. Laser sensors from ipf electronic form the basis here for measurement results that are always precise and repeatable.

"We developed the system about a year ago on behalf of an OEM in the automotive sector for a plant in Delhi (India). Therefore, it is designed as a manual workstation," explains Holger Fischer, Head of Business Development at BEAS Technology. The Chemnitz-based company plans, develops, realizes and optimizes fixtures as well as special machines, e.g. solutions for 3D printing, test benches, welding fixtures as well as assembly systems for drilling, deburring and joining gearbox components (including gearshift forks). With its in-house robotics studio, BEAS Technology also specializes in the simulation, development and start-up of robot applications as well as programming. The solutions and core competencies of the company are complemented by an extensive AZAV-certified training and education offer as well as various consulting services.