In the cathodic dip painting process of an automotive manufacturer, inductive proximity switches are used to inquire about the positions of a lifting device in a curing oven.

The coated parts enter the oven directly. The excess paint thus evaporates abruptly during the run-in process, precipitates as condensate and drips onto the system components. The inductive proximity switches must therefore be extremely tight because the condensate in the baking oven has much higher creep properties than water. In addition, the devices must not contain silicone, since outgassing of the material would cause burn-in defects on the coated parts.

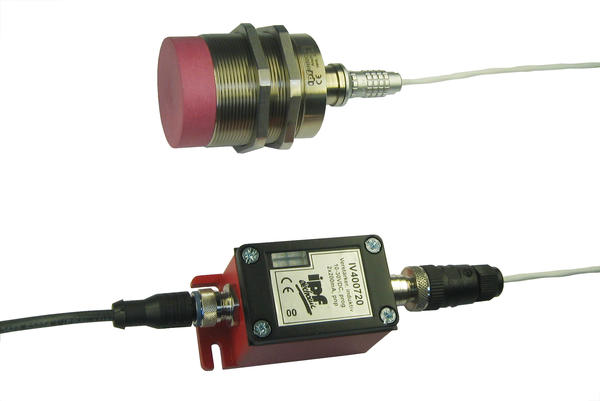

By using special seals and sealing systems, ipf electronic succeeded in developing an absolutely leak-proof and completely silicone-free high temperature sensor that prevents the condensate from penetrating and with its temperature resistance of maximum +230°C stands up to the high oven temperatures.

Since the solution is pluggable, the proximity switches can be replaced very quickly in case of mechanical damage.

The complete application report can be found in the PDF file below.